Insert 2 25 Teeth (toothed idlers) into each xy idler mount.

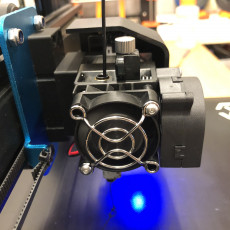

#Hemera 3d printer install

If your Bed y Extrusion is slightly to Long, Cut it a few mm, if it is to short, add some spacers or washers in between the z_back_carriage and the bed y Extrusion (See Picture).Lastly fix the 36 tooth pulley to the Back z Spindle.īut the 24 tooth pulleys onto the 3 steppers, install Them in the z-Motor-mounts and tighten the closed Loop belts while doing so.įirst mount the xy stepper motor mounts and xy idler mounts to the frame. Make sure you don't apply force to the spindle so you Bent it while tightening the Back screws. Mount the z-back-carriage to the bed y Extrusion using 6 M5 screws. Maybe you have to adjust the Position of the Back z top and bottom mount a little bit. Make Sure Everything stays square / perpendicular. Now move the bed y Extrusion into the back z carriage. Make Sure Bed x and y Extrusion are perpendicular and centered. First mount it to the bed x Extrusion using two M5x12 screws you Access through the holes drilled in the bed x Extrusion. Secure the z top mount to the frame.Now Install the Bed y Extrusion. You might have to loosen the Back Extrusion of the xy Gantry to get everything in. Slide the closed Loop belt and the 36 toothe pulley on the Spindle.Push everything into the bottom Back z Motor mount. Attach the Back z carriage to the Nut and LMK12LUU. Slide the Nut and the LMK12LUU bearing on. Slide the trapezoidal Spindle into there as well. Push the 12mm smooth rods in the top z-mounts. Install the top Spindle mount on both Front z-axis.Attach the Bed x Extrusion to the z-carriages. Put on the leadscrew nut and LMK12LUU bearing. Attach the 36 tooth pulley to the Spindle and Slide on the closed Loop belt.Slide on the z-carriage. Push the 12mm smooth rods in the Front Motor mounts. The front mounts are mounted adjacent to the vertical extrusion, the Back one has to be in the Center of the Back bottom extrusion.Now Install the 608 bearings in the top mount of the z-spindles. The assembly of these 3 pieces is nearly identical.First install the pillow bearings in the bottom motor holders. The z-Stage consists of 3 Sets of Spindles and smooth rods. Measure the diagonals of each side of the frame to ensure, everything is square. Afterwards Install the 3 horizontal profiles for the xy Gantry. You can tighten the screws through the holes previously drilled. Use a square in addition to be sure everything is Assembled correctly.Start with the 4 bottom and 4 vertical extrusion profile, connecting each set of profiles using 2 M5x12 Button Head screws. The assembly has to be done on a smooth and even surface to ensure the frame is square. Additionally Drill the two holes in the Center of the Bed x Extrusion for assembly. Use the Template to find the right position, you may refer to the drawings as well. The 2 front z extrusions need 2, the Back 4, additional holes at height of the xy Stage.

On the top and bottom and each Extrusion needs a total of 4 holes.

You also have to Drill the access holes for the screws in the vertical z Extrusion. Also tap both ends of bed y and x-axis extrusion. If you want to use feet or rollers for the printer drill the appropriate holes into the vertical extrusion. You can also ask me to design something but my time is limited.įrame Assembly ist pretty straight forward.įirst Tap all horizontal extrusion profiles using a M5 tap (each horizontal xy extrusion needs to be tapped 4 Times).

#Hemera 3d printer free

If you have any other ideas on what you want to see on the machine feel free to design and share it with the community. The design an parts I used are tailored to what I am comfortable with. The printers design was kept mostly simple so it can be adapted to your needs. Bondtech Dual Drive Gear Extruder- Inductive Probe for Bed Leveling.E3D V6 or E3D Volcano Hotend (Up to 1.2mm nozzle size).Duet 3 6HC Controller (Others possible).12mm Cast Aluminium bed- 2000W 230VAC Silicone Heate.10mm belts for xy Motion- drag Chain for XY-Gantry.Open Source- Triple z axis for automatic bed leveling.Frame Built from 2040 Extrusion with blind Corner Connections (similar to Voron).Large Built Volume- budget-friendly (relativly).For Lager Sizes you need to change over to 15mm belts.Main Features: The machine I buillt has a built volume of 410x410x410mm (otherwise it would not fit trough my door).įrom the rigidity of the frame and motion components I'd trust the system up to 650圆50mm with reasonable speeds in xy direction. The printer was developed in collaboration with Allgäutec to get the most performance out of the motion components.Some of the electronics were provided by CR3D. The main goal was to make the built more affordable, easier and cheaper to built.For this reason the linear rails were replaced by rollers in an aluminium profiles. Here I present you the new version of my large format CoreXY 3D printer known as CoreBot.

0 kommentar(er)

0 kommentar(er)